Marble polishing pads are believed to be familiar to everyone. Because marble floors are widely used in public places, shopping malls, supermarkets, etc., due to the large number of people, it is inevitable that the marble floor will wear out over time. At this time, marble polishing pads will be used, and the ground needs to be refurbished. When it comes to this, many people have already basically understood this product, but after all, there are still many people who are confused about the use of this product. Know how to use it to achieve the effect of ground renovation.

This article will detail and describe some of the considerations in the use and use of the polishing pad from each step used in the marble polishing pad.

1. Clean the surface of the ground. Use a tool to remove the concrete slurry from the gap in the stone. Then remove the dust thoroughly with a brush or a vacuum cleaner. Use a dry and clean ground to clean and clean the ground without sand and impurities.

2. After the overall cleaning of the stone surface is completed, the small damaged points and the stone joints on each stone are repaired with marble glue, and the original damaged surface is first repaired with marble glue close to the stone color. Then use the stone slitting machine to re-cut the slit in the original stone installation to make the width of the gap, and then fill it with marble glue close to the stone color. After the marble glue is repaired, it must be dried before the glue can be dried.

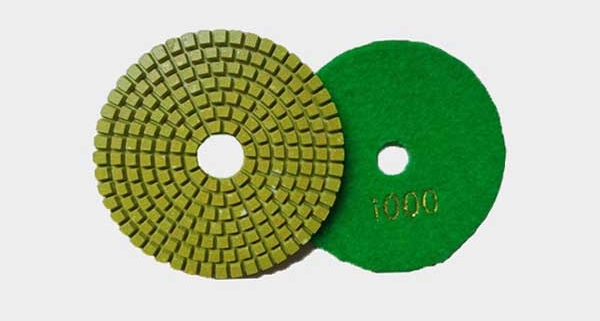

3. After the marble glue is dried, use the sander to polish the whole ground, and polish the whole horizontally. Focus on the caulking between the stones and the edge of the wall, the decorative shape and the special shape to keep the whole stone floor level. Finishing the polishing, re-creating the marble glue, caulking, caulking, and continuing the secondary grinding. Then use the stone refurbished machine with the steel stone polishing pad from coarse to fine. A total of seven polishing and finishing finishes are required. Smooth, and then polished with steel wool, the polishing degree reaches the brightness required by the design, there is no obvious gap between the stones.

4. After the polishing is completed, use the water suction machine to treat the moisture on the ground. At the same time, use the blow dryer to dry the whole stone floor. If time permits, you can also use natural air drying to keep the stone surface dry.

5. Spray the syrup evenly on the ground side. Use a marble polishing machine to grind the enamel. Use a washing machine with a red scouring pad. Sprinkle the syrup with the same amount of water on the ground. Start grinding and heat. The crystal surface material is crystallized on the surface of the stone. The surface fruit formed after the transformation.

6. The overall ground maintenance treatment: If it is a large gap of stone to be treated with marble protective agent ‚ re-polishing times to increase the hardness of the entire surface of the crystal face.

7. Ground cleaning and maintenance: When the stone surface is formed into a crystal mirror, use a vacuum cleaner to absorb the residue and moisture on the ground. After polishing, use a polishing pad to make the whole surface dry and bright. If the surface is damaged, local maintenance can be performed. Construction can be done at any time.

Marble polishing pad has traditional and standardized grain color and good flexibility. It is widely used in the processing of marble, artificial stone and other lines, curved veneer and special-shaped stone. It has multiple shapes and can be used for various grain sizes. Different colors can be used to distinguish them according to different needs of customers. Therefore, it is not enough to use only polishing pads. In the following process, you should also pay attention to these aspects:

1. When abnormal sounds and vibrations, rough cutting surfaces or odors are found, the work must be terminated immediately, and the fault should be checked and eliminated in time to avoid accidents.

2. When working, the workpiece should be fixed, the profile should be oriented with the direction of the tool to avoid abnormal cutting, no side pressure or curve cutting, smooth knife feeding, avoiding the impact of the blade and the workpiece, resulting in saw blade damage, or workpiece Flying out, causing an accident.

3. When cutting and stopping cutting, do not be too fast to avoid broken and broken teeth.

4. If cutting aluminum alloy or other metal, use special cooling lubricant to prevent the saw blade from overheating, causing damage such as paste and affecting the cutting quality.

5. The equipment discharge slag tank and slag suction device ensure the smooth flow of water, prevent slag agglomeration and affect production and safety.

6. Dry cutting, do not cut for a long time, so as not to affect the service life of the saw blade and cut fruit; when cutting wet, it should be cut with water to prevent leakage.

The above is a complete introduction to the use of marble polishing pads. I believe that through the above introduction, we can use polishing pads more flexibly and safely.