From the shimmering, fluid curves of a landmark cultural center to the crisp, minimalist lines of a contemporary skyscraper, aluminum sheet has become one of the most defining materials of modern and contemporary architecture. More than just a functional metal, aluminum has provided architects with a versatile and expressive medium to realize ambitious designs that were previously unimaginable.

Aluminum sheet has become a highly popular material in modern architecture due to its unique combination of aesthetic versatility, structural properties, and sustainability.

Applications of Aluminum Sheet in Modern Architecture

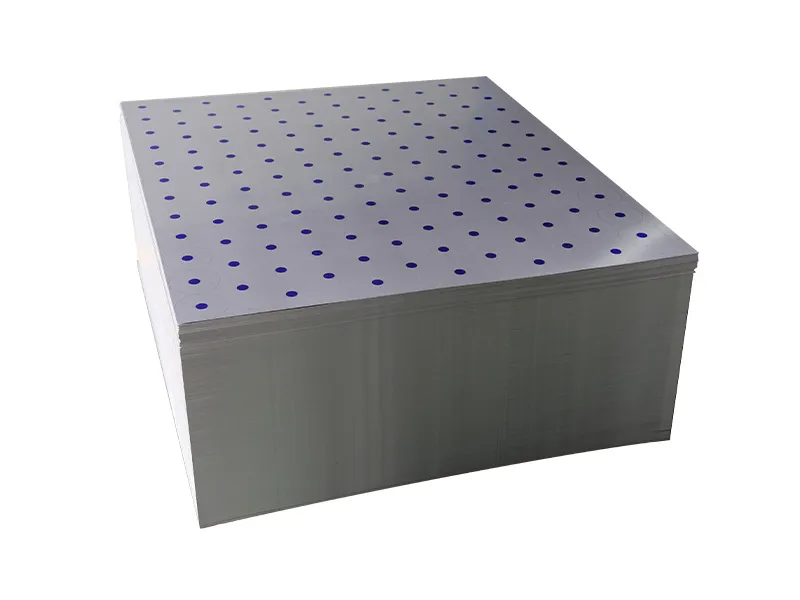

Facades and Cladding: This is one of the most common applications. Aluminum panels, including aluminum composite materials (ACM) and perforated sheets, are extensively used for exterior walls, providing a sleek, modern appearance and protection against weather. They can be customized with various finishes, colors, and patterns.

Roofing Systems: Lightweight and corrosion-resistant, aluminum is an excellent choice for both residential and commercial roofing, including standing seam systems and shingles. Its reflective properties also contribute to energy efficiency by reducing heat absorption.

Windows and Doors: Aluminum is widely used for window and door frames due to its strength, durability, and ability to support large glass panels. Modern aluminum window frames often incorporate thermal breaks for improved energy efficiency.

Curtain Walls: As non-structural exterior walls, curtain walls frequently utilize aluminum for their framing, allowing for large, transparent surfaces that maximize natural light.

…

More detailed information about the application and features of aluminum sheet in modern architecture can be found by clicking visit: https://www.dw-al.com/a/news/aluminum-sheet-in-modern-architecture-applications.html