Floor paint construction often encounters the phenomenon that the newly installed polishing pad has been consumed too quickly before it has been used. So what is causing the polishing pad to run out too quickly?

The reason for the fast consumption of polishing pads

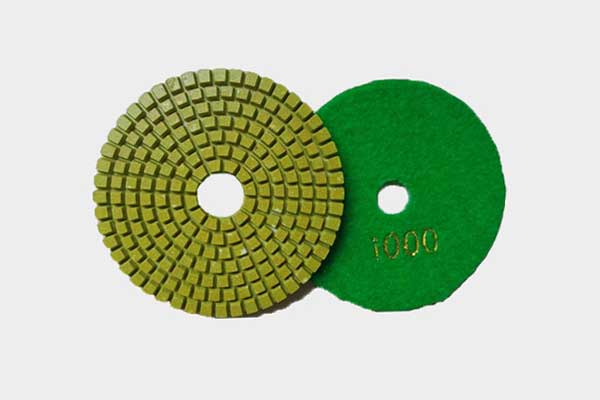

The polishing pad is divided into soft foundation, medium foundation and hard foundation. Hard foundation polishing pads are used for the ground with poor compactness. Soft foundation polishing pads are used for better quality. Generally, it is sufficient to use medium foundation for the ground. During the initial construction period, some concrete The quality of the ground is relatively poor, especially in the case of some old ground renovations. The flatness is poor, the ground is loose, and the water mill treatment is prone to generate a lot of mud, which causes the polishing pad to be consumed very quickly. The main reason for polishing pad consumption.

Solution

1. For the ground with poor quality, it is recommended that you use medium and large floor grinders, spray dry on the ground, and then use dry grinding. Select a hard-based metal polishing pad No. 30 and loosen the surface layer before leveling. Processing, then use a 100-type hard or soft base metal polishing pad and then process and polish, the basic hardness and flatness are not all processed, and the subsequent work is much simpler.

2. If you encounter sand with poor ground foundation density and the polishing pad will wear each other, so it is easy to accelerate the consumption of the polishing pad. At this time, we can first perform purification treatment to achieve higher ground density. Polishing later can save the use of polishing pads.

3. It is recommended to use diamond polishing pads or thick concrete polishing pads for ground leveling and rough grinding. Fine sand polishing pads can be used without coarse sand polishing pads.

4. It is recommended to use sharp resin polishing pads for hard concrete floors, increase machine counterweight, reduce mill speed, and reduce forward speed.

5. It is recommended to use durable resin polishing pads for soft concrete floors, increase the speed of the mill, and accelerate the forward speed.

6. When using the polishing pad, do not use jump numbers. According to the normal use situation, dry grinding is more consumable than water grinding, but water grinding treatment will make the ground more uniform and delicate.

From the above understanding, we know that in the early stage of the construction of wear-resistant floors, the quality of most concrete floors is not very good, especially for the refurbishment of some old floors, the flatness is not good, the ground is loose, and the hardness is poor. Mud, causing the polishing pad to be consumed particularly quickly. At this time we need to choose different polishing pads for different floors.