In today’s highly competitive industrial environment, heavy machinery has become indispensable for manufacturing, mining, metal processing, logistics, and large-scale construction. As these operations scale up, enterprises need not only advanced equipment but also a stable, safe, and efficient facility to support daily production. Steel structure factories have therefore emerged as the preferred solution for heavy machinery companies, offering unmatched strength, adaptability, and long-term reliability.

Why Steel Structure Factories Are the Ideal Choice for Heavy Machinery

Steel structures stand out from traditional concrete buildings for a variety of structural and operational benefits. For facilities that accommodate oversized equipment and continuous heavy-duty workloads, the advantages become even more apparent.

1. Superior Load-Bearing Performance

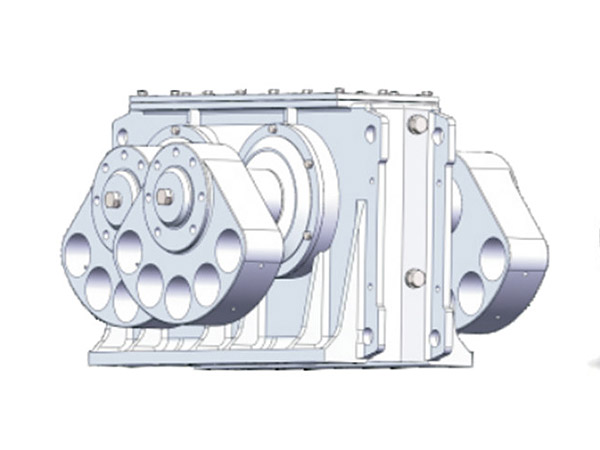

Heavy machinery such as rolling mills, welding rotators, industrial furnaces, and mining equipment can impose massive static and dynamic loads.

Steel’s high tensile strength allows the entire building to remain structurally stable even under extreme load conditions. When properly engineered, steel factories can support overhead cranes, rail systems, and vibration-prone machinery without compromising safety or lifespan.

2. Column-Free, Flexible Interior Layout

Many industrial processes require large open spaces for equipment installation, maintenance access, and material flow.

Steel frame systems can achieve wide spans—often 20 to 60 meters—without intermediate columns, giving factories greater freedom in layout planning and simplifying future equipment upgrades or production line adjustments.

3. Long-Term Durability with Lower Maintenance

Modern steel structures are treated with anti-corrosion coatings, fire-resistant layers, and high-performance insulation materials. This ensures prolonged service life even in challenging environments such as coastal regions, high-humidity workshops, or areas with large temperature fluctuations.

Compared with concrete buildings, steel factories require less frequent repairs, helping enterprises reduce long-term operational costs.

4. Faster Construction and Earlier Commissioning

Most steel components are prefabricated in controlled factory environments before being delivered to the construction site.

This reduces on-site labor, shortens project timelines, and allows companies to put new heavy machinery into operation sooner—an essential advantage in fast-growing industries.

…

For more detailed information on the performance of steel structure workshops for heavy machinery and equipment, please click to visit: https://www.meichensteel.com/a/news/performance-of-steel-structure-factory-for-heavy-machinery-and-equipment.html