Tapered roller bearings are a type of rolling element bearing designed to handle both radial and axial loads by providing a conical shape to the rollers. This design allows the bearings to support heavy axial and radial loads and is commonly used in applications such as automotive wheel hubs, gearboxes, and other machinery. There are various types of tapered roller bearings, and they can be classified based on different factors such as cone and cup design, cage type, and precision class.

Tapered roller bearings types

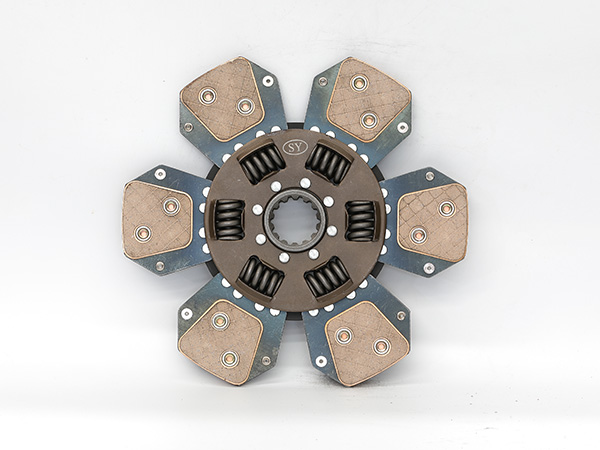

Single-Row Tapered Roller Bearings

These bearings consist of a single cone (inner ring) and cup (outer ring). They are the most basic and widely used type of tapered roller bearings. They can support both radial and axial loads in one direction.

Double-Row Tapered Roller Bearings

Double-row tapered roller bearings have two rows of rollers arranged in a back-to-back configuration. This design increases the axial load-carrying capacity and provides high stiffness. These bearings are commonly used in heavy-duty applications.

Four-Row Tapered Roller Bearings

Four-row tapered roller bearings have four rows of rollers arranged in two inner and two outer races. They are used in heavy machinery, such as rolling mills, where high radial and axial loads are present.

…

More detailed information about tapered roller bearing types can be found here: https://www.prsbearings.com/a/news/tapered-roller-bearings-types.html