A briquetting machine, also known as a briquette press or briquette maker, is a device that uses pressure to turn various forms of loose raw materials, such as biomass, wood shavings, sawdust, and agricultural residues, into high-density, compacted, and consistent-shaped briquettes. These briquettes can serve as a renewable and efficient energy source or as a raw material for various industrial processes.

For more details about the briquetting machine meaning, please visit:Briquetting Machine meaning, use, price, picture

Briquetting Machine Type

Screw Extruder Briquetting Machines:

Working Principle: These machines use a screw to compress the material through a tapered die.

Hydraulic Briquetting Machines:

Working Principle: Hydraulic systems generate high pressure to compress materials in a hydraulic cylinder.

Mechanical Press Briquetting Machines:

Working Principle: Operate using a mechanical eccentric action to compress materials.

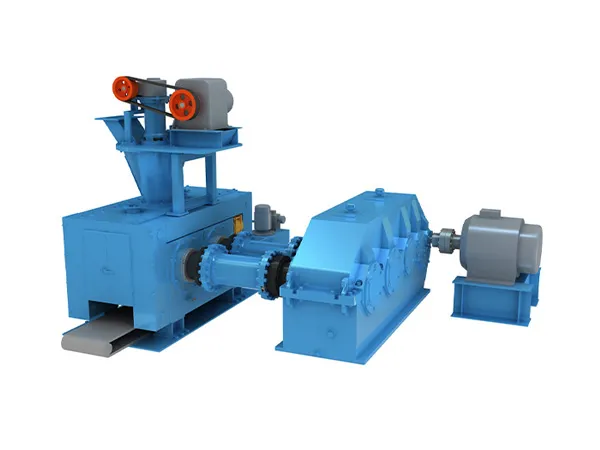

Roller Press Briquetting Machines:

Working Principle: Two counter-rotating rollers compact the material into briquettes.

Piston Press Briquetting Machines:

Working Principle: A reciprocating piston compresses the material in a closed chamber.

Screw Press Briquetting Machines:

Working Principle: Similar to screw extruders, these machines use a screw to push the material through a die.

Punching Briquetting Machines:

Working Principle: Use a punching mechanism to compact the material in a closed die.

Heat Press Briquetting Machines:

Working Principle: Utilize heat to soften the material before compacting it.

Briquetting process

Material Preparation:

Raw Material Selection: Choose appropriate raw materials such as biomass residues (sawdust, crop straw, etc.), industrial by-products, or other suitable materials.

Size Reduction: Grind or chop the raw materials to reduce their size, facilitating the briquetting process.

Drying (Optional):

Moisture Content Reduction: If the raw materials contain excess moisture, drying may be necessary to achieve the desired moisture content. This step improves the efficiency of the briquetting process.

…

For more detailed information on how to choose a briquetting machine, please click here: https://www.zymining.com/en/a/news/briquetting-machine-choose.html