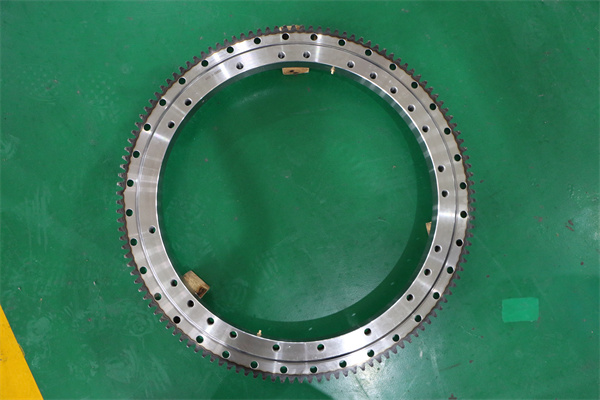

Replacing the slewing bearing on an excavator is an important maintenance task that helps to ensure the safety and reliability of the equipment. It is important to follow the manufacturer’s recommendations for replacement intervals and to have the work performed by a qualified technician with experience in heavy equipment maintenance and repair.

There are several reasons why the slewing bearing on an excavator may need to be replaced. Here are some of the most common:

Wear and tear: Over time, the slewing bearing may wear out due to the constant movement and weight that it is subjected to. This can cause the bearing to become loose or develop play, which can affect the stability and performance of the excavator.

Damage: The slewing bearing can also become damaged due to external factors such as impact or exposure to harsh environments. If the bearing is cracked or otherwise compromised, it may need to be replaced to prevent further damage or failure.

Corrosion: If the excavator is used in environments where it is exposed to saltwater or other corrosive substances, the slewing bearing may become corroded and damaged over time. This can affect the integrity and functionality of the bearing, requiring replacement.

Maintenance: In some cases, the slewing bearing may need to be replaced as part of a regular maintenance schedule. This is done to prevent any potential issues from developing and to ensure that the excavator continues to operate smoothly and efficiently.

Replacing the slewing bearing on an excavator can be a complex task and requires careful planning and execution. Here are the general steps involved:

…

For more detailed information on the replacement of excavator slewing bearings, please click to visit:https://www.excavatorbearing.com/a/bearing-knowledge/excavator-slewing-bearing-replacement-process.html