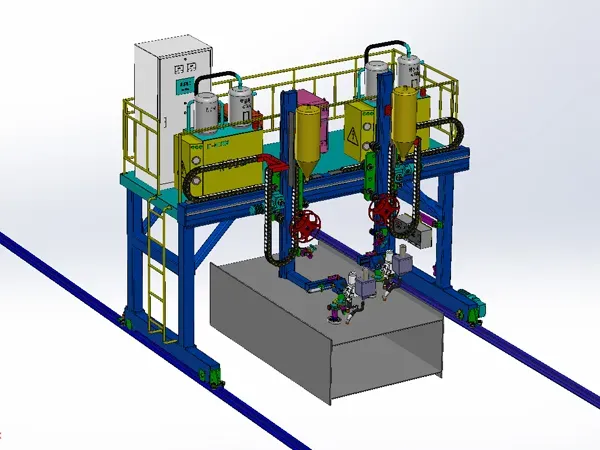

Gantry welding machine dominate the field of large-scale workpiece welding such as shipbuilding, engineering machinery, and bridge steel structures due to their high stability, wide coverage, and intelligent control system. This article deeply analyzes the advantages of gantry welding machines and provides professional reference for enterprise equipment selection.

1. Ultra-large workpiece welding capacity: the horizontal span can reach 3-20 meters, and the maximum longitudinal stroke is 50 meters, which is suitable for ultra-long parts such as wind turbine towers and ship sections. X/Y/Z three-axis precision movement, with a ±180° rotating table, can achieve full coverage of three-dimensional welds, and the static load-bearing capacity is up to 200 tons (heavy-duty model), which meets the welding needs of heavy workpieces such as pressure vessels and shield machine shells. Compared with cantilever welding machines, the rigidity of the gantry structure is increased by more than 60%, which greatly reduces the welding deformation caused by workpiece vibration.

2. Industry-leading welding accuracy and consistency: repeated positioning accuracy of ±0.05mm, ensuring that the straightness error of long welds (>10 meters) is ≤1mm/meter, supporting laser tracking or arc sensing real-time correction, and adapting to groove deviation. At the same time, the gantry welding machine can be equipped with 2-4 welding guns for synchronous welding, which increases efficiency by 300%. Each welding gun has independent parameter control (current 200-600A adjustable), which meets the requirements of multi-layer and multi-pass welding process.

3. Fully automated production: the gantry welding machine can realize one-click programming: import CAD drawings to automatically generate welding paths, reduce manual teaching time, support offline programming, and increase equipment utilization by 40%. It also has an adaptive process library that can store more than 500 sets of welding parameters (such as MAG welding, submerged arc welding, narrow gap welding), and automatically match material thickness (6-150mm)

…

More detailed information about the advantage of gantry welding machine can be found by visiting:https://www.bota-weld.com/en/a/news/advantages-of-gantry-welding-machine.html