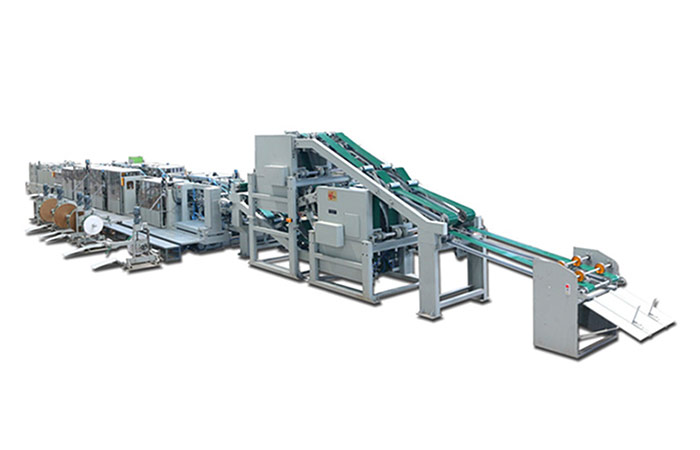

Choosing a valve bag making machine involves considering various factors to ensure that the machine meets your production needs, quality requirements, and budget. Valve bags are commonly used for packaging bulk materials like cement, chemicals, minerals, and agricultural products.

The key factors to consider when selecting a valve bag making machine

- Bag Size and Style: Determine the range of bag sizes and styles (e.g., dimensions, valve types) that you need the machine to produce. Some machines are designed for specific bag sizes, while others offer flexibility to accommodate a range of sizes.

- Production Capacity: Assess your production requirements in terms of bags per minute or bags per hour. Choose a machine that can handle your desired production rate while maintaining consistent quality.

- Material Compatibility: Consider the types of materials you plan to use for the bags. Different bag making machines are optimized for specific materials, such as paper, woven polypropylene, or other plastics. Ensure that the machine is compatible with your chosen bag material.

- Bag Quality: The quality of the bags produced is crucial. Look for a machine that can consistently produce bags with accurate dimensions, strong seals, and proper valve attachment. Quality control features like tension control and alignment systems can contribute to better bag quality.

- Automation and Features: Evaluate the level of automation the machine offers. Some machines come with advanced features like automatic tension control, servo-driven systems, and touchscreen interfaces for easy operation and precise control.

…

For more detailed information on how to choose a valve bag making machine, please click to visit: https://www.lyhuatianm.com/products-information/valve-bag-making-machine-selection.html