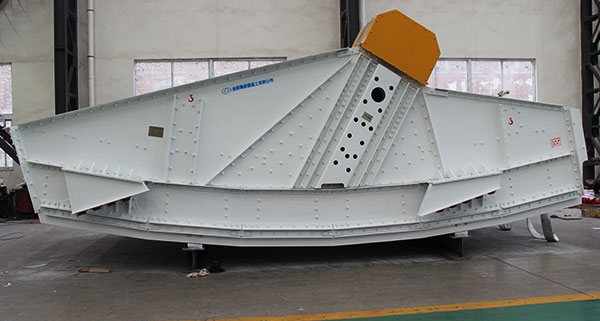

Nowadays, the coal slime content in the products of the coal industry increases and contains a lot of water, which brings certain difficulties to the dehydration of coal slime. In the past, the investment in the water treatment of coal slime was relatively large, which was not conducive to the control of production costs, but now the high-frequency dewatering vibrating screen is used, which has the characteristics of large processing capacity and simple process system, which can well dewater the coal slime. High-frequency dewatering screen is a kind of vibrating screen with high frequency and high vibration intensity as the main features. It is suitable for wet separation and solid-liquid separation of fine-grained materials. The vibrating screen manufacturer summarized the working principle of the high-frequency dewatering vibrating screen and introduced the high-frequency dewatering vibrating screen in detail.

Working principle of high frequency dewatering vibrating screen

The working principle of the high-frequency dewatering vibrating screen is to use high-frequency vibration to destroy the surface tension of the pulp, and the fine-grained materials will vibrate at a high speed on the screen surface to accelerate the separation of large-density minerals, and increase the contact between the materials smaller than the separation-sized materials and the screen holes. Probability, double vibration motor or flange type vibration exciter, the two motors are driven outside to make self-synchronized rotation in opposite directions, so that the screen body performs periodic reciprocating motion along a straight line, and fine-grained materials can be quickly screened out through the screen holes , in order to achieve the purpose of screening and dehydration.

Because the high frequency screen adopts high frequency, on the one hand, it destroys the tension on the surface of the pulp and the high-speed oscillation of the fine-grained materials on the screen surface, accelerates the separation of the large-density useful minerals, and increases the contact between the materials smaller than the separation size and the sieve holes. probability. Therefore, better separation conditions are created, so that the materials smaller than the separation particle size, especially the particles with large specific gravity, together with the ore pulp, pass through the sieve holes to become the under-sieve product.

Workflow of high frequency dewatering vibrating screen

1. Two vibration motors with the same parameters installed on the excitation beam symmetrically rotate in opposite directions when they are connected to electricity, and each generates an equal centrifugal force, and the components of the two forces in the vertical vibration direction cancel each other out in opposite directions;

2. The component forces in the parallel vibration direction are superimposed on each other to form a linear vibration force, and the linear vibration force continuously acts on the screen body in a reciprocating cycle, so that the screen body vibrates on the buffer spring;

3. At the same time, the buffer spring reduces the dynamic load of the screen body to the support foundation of the screen machine, and the screen body drives the screen surface to vibrate synchronously, and transmits the force to the material on the screen;

4. The impact material is thrown up on the screen surface to advance for dehydration, the material is continuously input from the feeding chute, and dehydrated through the screen surface, the under-screen material is discharged into the under-screen chute, and the over-screen material is discharged into the discharge chute.

…

Details can be accessed by clicking here:https://www.hsd-industry.com/news/the-working-principle-of-high-frequency-dehydration-vibrating-screen/