Because of the long-term use of marble, the crystal surface brightness and gloss disappeared on the marble surface, which affects the overall decoration design inside the home. Then, when the brightness and gloss of the marble polishing pad disappear, what method can be used to make the marble polishing pad re What about the glow? Generally in this case, we need to polish the marble to re-gloss the crystal face of the marble.

When marble is polished, different polishing and polishing processes are used depending on the type of marble, and the polishing process of the flat plate is different from the polishing process of the arc panel. Therefore, we should pay attention to the following when polishing and polishing.

1. After continuous polishing of the crystal layer and crystal layer after polishing the stone grinding block (commonly known as crystal face care), the pores are not completely closed, and the stone can be breathed inside and outside, and the stone is not easy to be diseased. At the same time, it has a certain waterproof and antifouling effect.

2. After the marble waxing and polishing, the stone pores are completely closed, the stone can not be breathable inside and outside, so the stone is prone to lesions.

The difference between marble polishing and wax polishing

Marble polishing and waxing and polishing can make the stone bright and beautiful, so what is the difference between the two? The best polishing pad manufacturers below mainly introduce the difference between the two in terms of essence, appearance and extension operation.

At present, stone surface treatment is one of the most ideal curing methods for marble. It does not change the structure of the stone, so it does not change the texture of the original stone. After the crystal surface treatment, the stone surface molecules are denser, and the gloss brightness is obviously improved, making the stone surface brighter and more noble. Stone waxing can make the stone color bright. Stone wax is a water-soluble material. When it is used, it will produce a protective film on the top of the product. This will improve the brightness of the stone, but its protective effect on the stone is Limited, poor weather resistance, anti-fouling effect is not ideal, and it is easy to attach dust.

Nowadays, people also find that waxing also causes some harm to the stone, because it is applied as an airtight cover protection material on the surface of the stone. After the pores of the stone are closed, the moisture inside and behind the surface is not released. In the interior of the stone, the stone has been damaged for a long time. Marble grinding is the last step in the process of stone care crystal surface processing or stone light board processing. It is one of the most important processes in today’s stone care, which is different from the marble cleaning and waxing polishing in the traditional sense of cleaning company business.

First, the essential difference

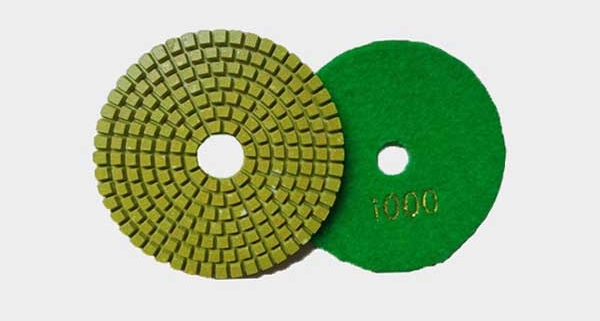

1. Marble grinding polishing is a prelude to stone surface treatment or a necessary process in stone processing. The main principle is to use the pressed grinding block synthesized by mineral acid, metal oxide and other materials to match the pressure of mechanical grinding disc, high-speed grinding force, frictional heat energy, and the physical and chemical cooperation of water on the smooth surface of marble. Thereby forming a new layer of bright crystals. This crystal layer has an ultra-bright, clear luminosity. The luminosity can reach 90-100 degrees. This crystal layer is a modified crystal layer of a stone surface layer (1-2 mm thick).

2. Marble cleaning is a prelude to marble waxing and polishing, marble cleaning waxing polishing is a relatively popular marble cleaning and maintenance protection measures in the early 80s-90s, and now has lost the market and the meaning of existence. Its essence is a thin coating of acrylic resin and emulsion polymer covered on the surface of the new stone (polished board), which is often referred to as water wax or floor wax. The high-speed, low-pressure polishing machine is combined with the fiber mat to rub the surface of the stone to make the resin coating more bright. Due to the product update, later appeared special light wax, wax-free, etc., this coating is similar to the oil varnish on the wooden floor.

3. The polishing process of the grinding block before the marble care crystal surface treatment is the physical and chemical cooperation process between the stone surface layer and the chemical. The surface layer of the stone is completely integrated with the bottom layer, and there is no separation layer.

4. The wax layer on the marble waxing is attached to the surface of the stone, a layer of resin film, and there is no chemical reaction with the stone itself. This wax layer can be shoveled with a blade to cut the wax film off the surface of the stone.

Second, the difference between representation

1. Polishing and polishing of marble grinding blocks is the prelude of crystal face care stone care. After polishing and polishing, the luminosity is high, the definition is high, the wear resistance, the resistance to stepping, and the scratching are not easy. It is the true embodiment and value extension of the stone use function.

2. The stone after polishing and polishing the luminosity is low, the luminosity is not clear, and it is very fuzzy, not wearable, not water resistant, easy to scratch, oxidized and yellow to reduce the essence of the stone.

Third, the difference between extension and operation

Generally speaking, the steps of the appeal can basically handle the marble surface, but sometimes we encounter artificial stone like jazz white and resin. After the completion, the surface may not be very bright, we can spray A2 again. The syrup is ground to 3000#, then repeated with nano-pad, with marble mirror complex cream NO2, 2X mirror lock bright knife into the milk Q5 for polishing, the effect of water bright will be much better than before.