Concrete dry polishing pad is a kind of polishing pad for dry grinding of the floor. There is also a polishing pad. Its usage is different. What is the difference? This is the question most asked by everyone, because they are different in nature, and the methods and types used are also different. Today, I will mainly explain the difference between different types of concrete dry polishing pads and water polishing pads.

Dry polishing pad

Dry polishing pads are mainly used for dry grinding processing of various types of stone surfaces. They are flexible processing tools made of diamond as abrasives and composite materials through special processes and formulas. They can be used for special-shaped processing of stone, ceramics, concrete and other materials. There is no need to add water during use, and it is not easy to dye. It can achieve the polishing effect of a water polishing pad. It has great advantages in saving water resources. It is being widely used in stone grinding and renovation projects in some special environments.

Dry polishing pad characteristics

1. Adopt the latest patent formula

2. It can achieve the polishing effect of water polishing pad

3. No scratches or color left on the stone after grinding and polishing (not easy to stain)

Use of dry polishing pad

1. The weight of the marble grinder is the key point, and only 150KG or more can be used for real leveling and grinding. If it is a small stone grinder with insufficient weight, there will be obvious waves, which is only suitable for small area or primary grinding or crystal surface For processing purposes.

2. When the marble grinder is grinding, if the water consumption is not well controlled, it is easy to induce the moisture reversal of the cement mortar at the bottom of the stone; the rise of calcium hydroxide white bloom.

3. In the polishing step, try to use weak acid or neutral stone polishing powder. The acidic polishing powder will burn the surface of the marble if it is too acid. The cheating method of not cleaning the residue after polishing will also erode and expand the lines and holes, which will cause many injuries. The sequelae of the hole, and cause annoying problems such as stone yellowing.

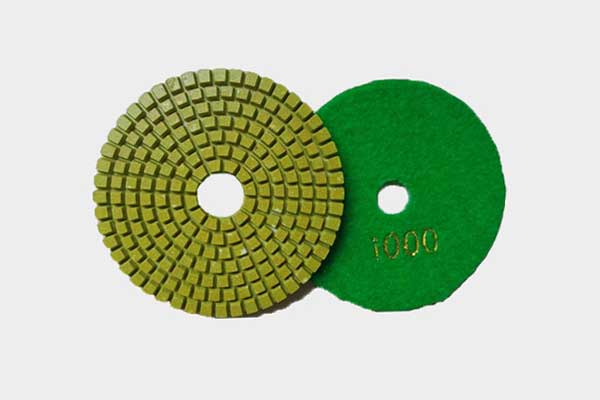

Polishing pad

The polishing pad is also called soft polishing pad. It is a flexible processing tool made of diamond as abrasive and combined with composite materials. The back is glued with Velcro cloth, which is fastened on the joint of the grinder for grinding. , Ceramics, glass, floor tiles and other materials for special-shaped processing, suitable for stone polishing, line chamfering, curved board and special-shaped stone processing, and can also be used for marble, coagulation, cement floors, terrazzo, glass-ceramics, artificial stones, floor tiles , Special-shaped processing, repair and renovation of glazed tiles and vitrified tiles.

Characteristics of polishing pad

It has strong grinding power, good durability, good softness, clarity and gloss. It is an ideal stone grinding tool. The whole process is divided into four stages: rough grinding, fine grinding, fine grinding and polishing. The processed stone , The gloss is over 90°.

Use of polishing pad

The polishing pad is suitable for portable electric or pneumatic grinders, and then the joint is connected, the power is 750-1500W, and the number of revolutions is 2000-10000. When working, apply a certain pressure to the machine while running water on the surface of the stone to be polished back and forth 4-5 times, then you can replace the finer polishing pad. Many people are accustomed to water polishing pads, because the water polishing pads are polished deeper, they are not prone to scratches, and there is no dust. Dry grinding is relatively shallow, and the amount of dust is relatively large, and scratches are easier to appear.