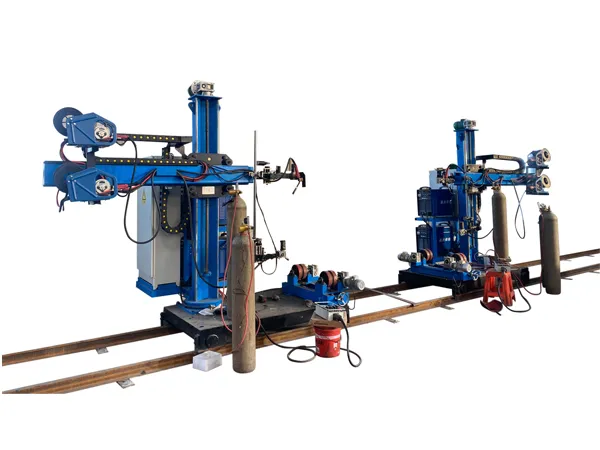

An automatic welding machine for pipes is a piece of equipment designed to automate the welding process in pipe fabrication. This type of machine is commonly used in industries such as oil and gas, construction, and manufacturing, where pipes need to be joined together through welding. Automatic welding machines offer advantages such as increased efficiency, consistency in weld quality, and reduced labor costs. Here are some key features and considerations for a pipe automatic welding machine:

Pipe automatic welding machine features

- Pipe Handling System:

The machine should have a mechanism for handling and rotating the pipes during the welding process. This ensures that the entire circumference of the pipe can be welded without manual intervention.

- Welding Power Source:

Utilizes a welding power source that is suitable for the specific welding process required (e.g., TIG, MIG, or submerged arc welding).

- Welding Head/ Torch:

Equipped with a welding head or torch designed for pipe welding, capable of moving along the pipe’s length and adapting to different pipe diameters.

- Control System:

Incorporates a control system to program welding parameters, control the movement of the welding torch, and manage the overall welding process.

…

For more detailed information about the considerations when choosing an automatic pipe welding machine, please click here: https://www.bota-weld.com/en/a/news/precautions-of-when-choosing-an-automatic-pipeline-welding-machine.html