Metal recycling has become a critical aspect of sustainable environmental practices and resource conservation. As industries generate substantial amounts of metal waste, innovative technologies are essential to process this waste efficiently. Metal briquetting machines have emerged as a groundbreaking solution, revolutionizing the way metal scraps are managed and recycled. This article delves into the technical aspects and benefits of metal briquetting machines in the context of modern waste management and recycling efforts.

I. Understanding Metal Briquetting Machines

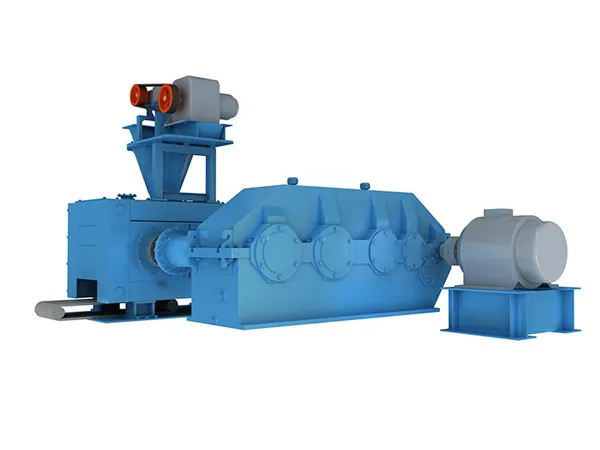

Metal briquetting machines are specialized equipment designed to compact metal scraps, such as steel, iron, aluminum, and copper, into dense, cylindrical briquettes. These machines use hydraulic pressure to compress metal waste, transforming loose chips, turnings, and shavings into compact, easy-to-handle briquettes.

II. Technical Components of Metal Briquetting Machines

- Feed System: Metal scraps are fed into the machine’s hopper, which transports them to the compression chamber.

- Compression Chamber: Hydraulic cylinders apply immense pressure to the metal scraps, forcing them into the desired briquette shape.

- Hydraulic System: Powerful hydraulic systems generate the force required for compression, ensuring consistent and high-quality briquette production.

- Cooling System: To prevent overheating during the compression process, some machines feature cooling systems that maintain optimal operating temperatures.

- Briquette Ejection System: Once the briquettes are formed, an ejection system pushes them out of the machine for collection and further processing.

III. Advantages of Metal Briquetting Machines

- Space Efficiency: Metal briquettes have a significantly reduced volume compared to loose scraps, optimizing storage and transportation space.

- Increased Value: Briquettes have a higher density, making them more valuable when sold to recycling facilities.

- Environmental Benefits: By compacting metal waste, briquetting machines minimize the environmental impact associated with landfill disposal and metal production.

- Energy Savings: Recycling metal through briquetting consumes less energy than processing raw materials, contributing to energy conservation efforts.

- Improved Workplace Safety: Compact metal briquettes are easier and safer to handle, reducing the risk of accidents associated with sharp metal scraps.

- Customization: Metal briquetting machines offer flexibility in briquette size and shape, catering to specific recycling requirements.

IV. Applications of Metal Briquetting Machines

- Automotive Industry: Metal briquetting machines process automotive scrap, including sheet metal, engine components, and wiring, into recyclable briquettes.

- Aerospace Sector: Aerospace manufacturers use these machines to recycle aluminum and titanium scraps generated during the production of aircraft components.

- Foundries: Metal briquetting machines assist foundries in recycling metal cuttings, mold scrap, and other waste materials, reducing costs and environmental impact.

- Machine Shops: Small and large machine shops use these machines to recycle metal turnings and shavings, ensuring sustainable waste management practices.

…

More detailed information about metal briquetting machines for metal recycling and waste management can be found here: https://www.zymining.com/en/a/news/metal-briquetting-machines-for-metal-recycling-and-waste-management.html