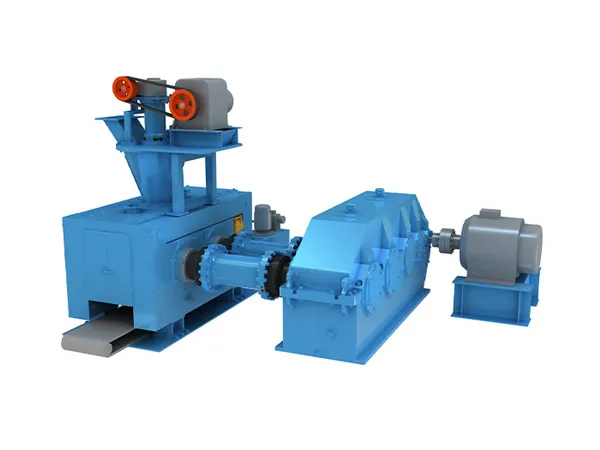

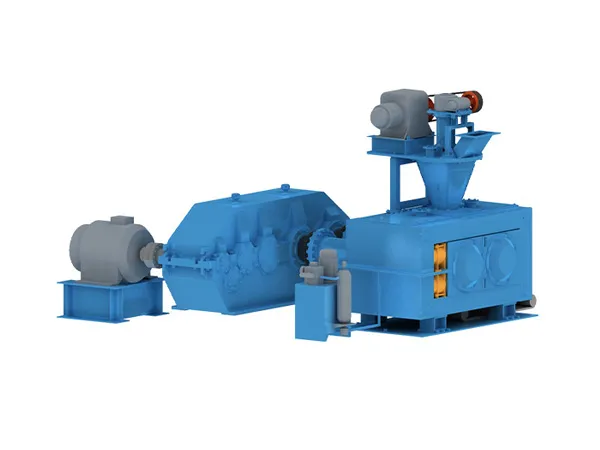

A briquetting machine is a valuable asset in industries ranging from biomass energy to metal recycling, playing a crucial role in turning raw materials into high-density briquettes. However, like any heavy-duty equipment, its performance and longevity largely depend on consistent and proper maintenance. Without routine care, issues such as wear and tear, material blockage, and mechanical failure can lead to costly downtime and reduced productivity.

How to maintain a briquetting machine for long lifespan

Maintaining a briquetting machine for a long lifespan is crucial for maximizing efficiency, minimizing downtime, and ensuring consistent production.

1. Implement a Robust Maintenance Schedule

Consistency is key. Develop and adhere to a detailed daily, weekly, monthly, and annual maintenance schedule.

Daily Maintenance:

Cleaning: Thoroughly clean dust, briquette debris, and other residue from the machine’s surface, especially the feed port, molding die, and discharge port. Use compressed air for hard-to-reach areas.

Visual Inspection: Inspect all accessible seals for cracks or oil residue, and check connections where cylinders meet the barrel or piston. Look for any signs of dampness.

Component Connection Check: Before starting, verify the tightness of connecting bolts between the motor and the main machine, and the fixing bolts of the molding mold.

Monitor Operations: Pay attention to unusual sounds, vibrations, or changes in performance. Address any abnormalities immediately.

Warm-up: Allow the machine to warm up for 5-8 minutes in colder weather before pushing it to maximum output.

Weekly/Bi-Weekly Maintenance:

Lubrication: Regularly lubricate bearings, screws, and transmission chains according to the manufacturer’s recommendations. Use the correct type and amount of lubricant.

Hydraulic System Check (for hydraulic machines): Monitor hydraulic pressure and temperature. Inspect hydraulic oil levels and condition, replacing it regularly. Check and replace hydraulic filters to remove impurities.

Monthly Maintenance:

Electrical System Check: Inspect wires for damage or aging. Clean dust inside the electrical control cabinet to prevent overheating of components.

Belt and Chain Tension: Check the tightness of belts and chains, adjusting them to the appropriate tension as per the instruction manual.

Quarterly/Bi-Annual/Annual Maintenance:

Main Mechanical Component Inspection: Inspect the wear of critical components like the screw (propeller/auger), molding die/mold, and pressure rollers.

Screw/Propeller: This is a key component. If severely worn, replace it promptly.

Molding Die/Mold: Check for wear, scratches, or depressions. Repair or replace if the molding size is inconsistent.

Pressure Roller: Inspect for wear, especially if processing abrasive materials.

…

For more detailed information on how to maintain the ball press to extend its service life, please click here: https://www.zymining.com/en/a/news/how-to-maintain-a-briquetting-machine-for-long-lifespan.html