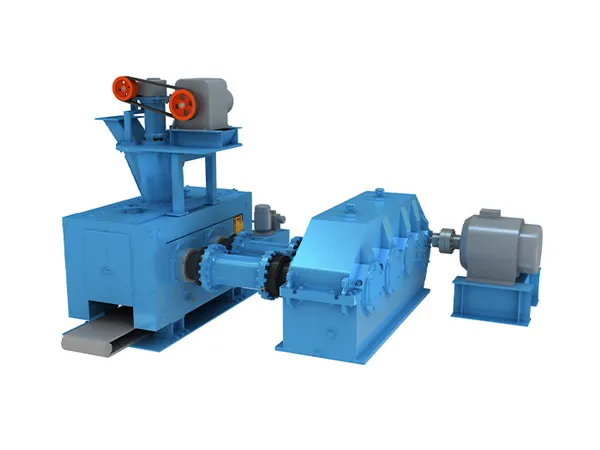

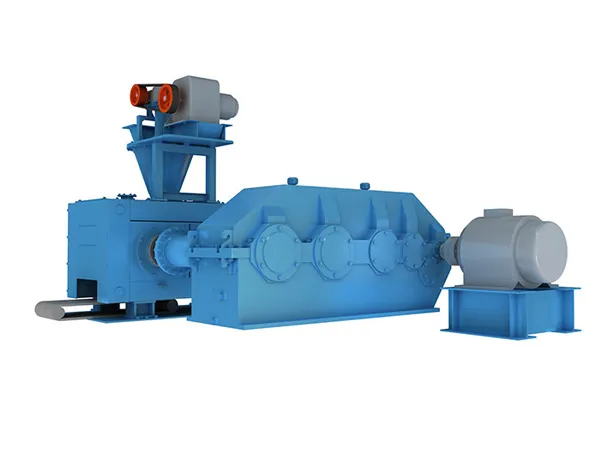

A briquetting press, also known as a briquette press or briquette machine, is a device used to convert various types of biomass, metal, or other materials into uniform, shaped briquettes. These briquettes are typically cylindrical in shape and can vary in size depending on the specific requirements of the application.

How does briquetting press work

Material Feeding: The raw material, which could be biomass (such as wood chips, sawdust, or agricultural residues), metal chips, or other types of material, is fed into the briquetting press. This can be done manually or through automated feeding systems, depending on the scale and complexity of the operation.

Compression Chamber: Inside the briquetting press, there is a compression chamber where the raw material is compacted under high pressure. This pressure is applied using a hydraulic system, mechanical system, or a combination of both.

Compression and Briquette Formation: As the raw material enters the compression chamber, it is subjected to high pressure, which compresses it into a dense mass. The pressure forces the material to bind together, forming briquettes of the desired shape and size. The shape of the briquettes can vary depending on the design of the press and any additional shaping attachments.

Ejection or Discharge: Once the briquettes are formed, they are ejected from the press either manually or through automated ejection systems. In some cases, the briquettes may need to be cooled or cured before they are ready for use or further processing.

…

More detailed information about how the briquetting machine works can be found here:https://www.zymining.com/en/a/news/how-does-briquetting-press-work.html