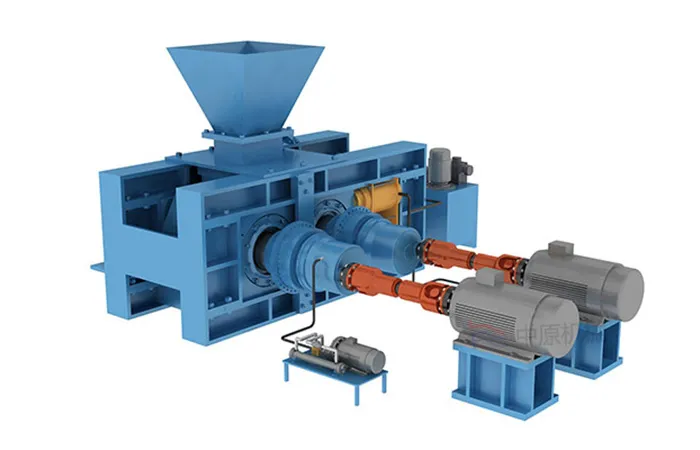

HPGR stands for high-pressure grinding rolls, which are a type of grinding equipment used in the mining and minerals processing industry. The structure of an HPGR typically consists of the following components:

Rolls: The HPGR consists of two counter-rotating rolls, often made of hard materials such as steel or tungsten carbide studs. These rolls exert high pressure on the feed material, crushing and grinding it against the fixed or floating roll.

Frame: The rolls are mounted within a sturdy frame, which provides support and stability to the entire HPGR unit.

Drive System: HPGRs are powered by a drive system, usually comprising motors, gearboxes, and other mechanical components, which rotate the rolls at the desired speed and torque.

Feed Hopper: The feed material is introduced into the HPGR through a feed hopper, where it is evenly distributed onto the rolls for grinding.

Adjustment Mechanism: HPGRs often include mechanisms for adjusting the gap between the rolls, allowing for control over the size of the crushed and ground material.

Hydraulic System: Many HPGRs utilize hydraulic systems to apply and control the high pressure exerted by the rolls onto the feed material.

…

For more detailed structural information about high-pressure grinding rolls, please click here: https://www.zymining.com/en/a/news/high-pressure-grinding-rolls-structure.html