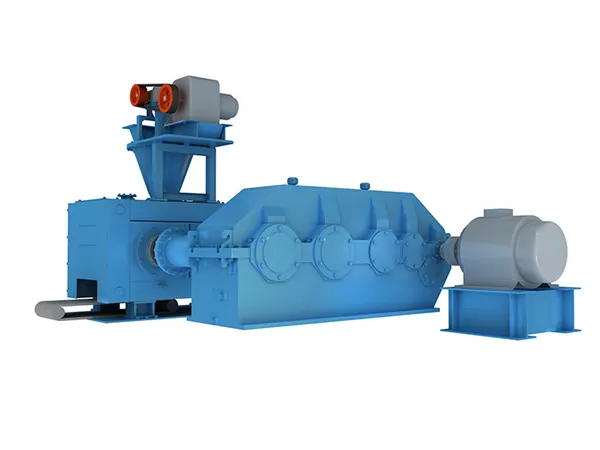

High-pressure Briquetting Machine Introduction

High-pressure briquetting machines have emerged as innovative solutions in the quest for sustainable waste management and efficient resource utilization. These machines play a pivotal role in converting various types of industrial and agricultural waste into compact, easy-to-transport, and energy-dense briquettes. This article explores the technical aspects and advancements in high-pressure briquetting machines, shedding light on their applications, working principles, and environmental benefits.

1. Working Principle

High-pressure briquetting machines utilize a dual-compaction process to transform raw materials into briquettes. The process involves applying intense pressure to compress the materials within a cylindrical chamber. This pressure induces plastic deformation in the material, causing it to bind together and form a cohesive briquette.

2. Components and Structure

Hydraulic System: The heart of a high-pressure briquetting machine is its hydraulic system. It consists of a hydraulic pump, control valves, and cylinders that generate and apply the necessary pressure for briquette formation.

Briquetting Chamber: The cylindrical chamber houses the raw material and facilitates the compaction process. It is designed to withstand high pressures and temperatures.

Feeding System: An efficient feeding system ensures a consistent and uniform supply of raw material to the briquetting chamber.

3. Material Compatibility

High-pressure briquetting machines can process a wide range of materials, including biomass residues, metal chips, and various industrial by-products. The versatility of these machines makes them invaluable in industries such as agriculture, metalworking, and manufacturing.

4. Applications

Biomass Briquetting: High-pressure briquetting machines are extensively used in the biomass industry to convert agricultural and forestry waste into biofuel briquettes. This process not only reduces waste but also provides a sustainable energy source.

Metal Chip Recycling: In metalworking industries, these machines compress metal chips and shavings into dense briquettes, facilitating easier handling, transportation, and recycling.

…

For more detailed information about the introduction of high-pressure briquetting machine, please click to visit:https://www.zymining.com/en/a/news/high-pressure-briquetting-machines.html