To check a swing bearing on an excavator, you can follow these steps:

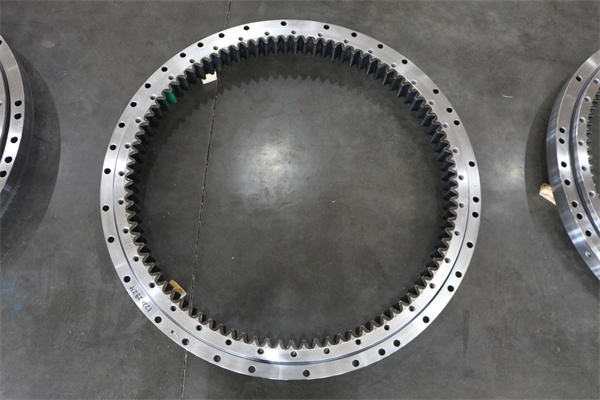

- Visually inspect the bearing: Look for any obvious signs of damage or wear, such as cracks, dents, or corrosion. Check for leaks or cracks in the oil seals, which can allow dirt and moisture to enter the bearing and cause damage.

- Check the swing mechanism for excessive play or binding: Check the swing arm, swing gear, and swing circle for any signs of looseness or binding. If the bearing is damaged, you may see excessive movement or tightness in the swing mechanism.

- Listen for unusual noise: Start the excavator and swing the boom. Listen for any unusual noises, such as grinding or growling sounds, which can indicate a damaged bearing.

- Check the oil level and condition: Check the oil level in the swing gear case and inspect the oil for contamination. Dirty or low oil levels can cause damage to the bearing.

- Use a dial indicator: If possible, use a dial indicator to check for excessive movement or runout in the swing bearing. Place the dial indicator on the bearing surface and rotate the bearing to check for any deviation from the normal position.

If you suspect that a swing bearing on an excavator is damaged, it is recommended that you stop using the machine and have it inspected by a qualified mechanic. A damaged bearing can cause excessive wear on other components and can lead to serious problems if left unchecked.

More information about excavator slewing bearings can be accessed by clicking:https://www.excavatorbearing.com/excavator.html