High-quality industrial sand is essential in construction, concrete production, glass manufacturing, and foundries. However, raw sand from rivers, quarries, or mines often contains impurities such as clay, silt, dust, and organic matter. To meet industry standards, sand must be cleaned efficiently—this is where sand washing machines come in.

This guide explains the types, working principles, industrial cleaning processes, and selection tips for sand washing machines, helping manufacturers improve sand quality, reduce labor, and ensure environmental compliance.

1. What is a Sand Washing Machine?

A sand washing machine is a device used to remove impurities and improve the quality of industrial sand. By washing away mud, dust, and light debris, it produces clean, uniform sand suitable for concrete, mortar, or other industrial uses.

Common Types of Sand Washing Machines

Wheel Sand Washer

Uses a rotating wheel to lift sand while water washes off impurities.

Ideal for medium to coarse sand.

Spiral Sand Washer

Employs a slow-rotating spiral to stir sand in water, separating mud and silt.

Suitable for fine sand and continuous operation.

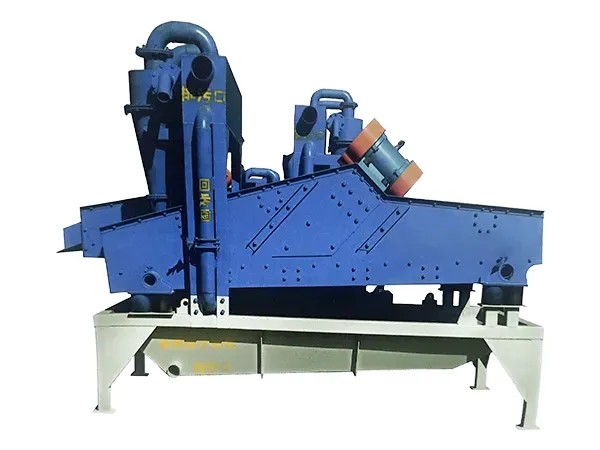

Rotary Drum Sand Washer

Rotating drum scrubs and separates sand from water.

Ideal for large-scale industrial sand processing.

Logwasher (Clay Removal)

Scrapes and agitates sticky sand to remove clay and heavy mud.

Commonly used in mining and high-clay-content sand.

2. How Sand Washing Machines Work

The basic principle is consistent: mechanical agitation and water flow remove impurities from sand.

a) Wheel Sand Washer

Sand is fed into a water tank.

Rotating wheels lift and wash the sand.

Mud and silt exit via overflow or drainage, while clean sand is discharged.

…

For more detailed information on sand washing machines, please click here: https://www.yd-crusher.com/a/news/sand-washing-machine-working-principle.html