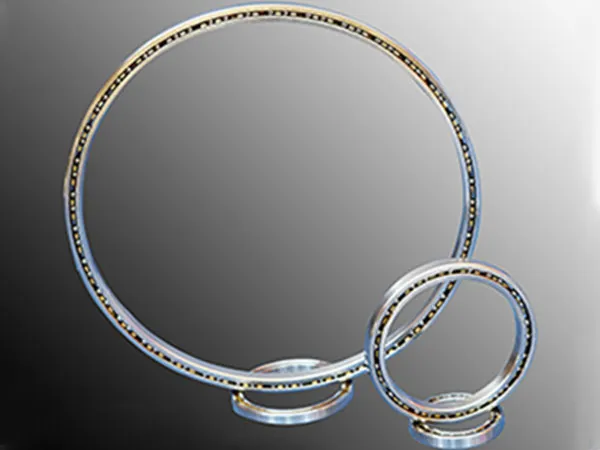

Thin section bearings are critical components in precision machinery, where compact design, high accuracy, and smooth operation are essential. They are widely used in robotics, aerospace, medical devices, semiconductor equipment, and industrial automation. Despite their slim profiles, these bearings must withstand significant loads and precise motion, which makes them particularly sensitive to installation errors, improper lubrication, and harsh operating conditions.

How to Extend the Life of Thin Section Bearings

Extending the life of thin section bearings is not just about maintenance—it requires a systematic approach combining proper selection, precise installation, lubrication, and continuous monitoring. The following guide provides practical, actionable tips to maximize performance and prevent premature failure.

1. Choose the Right Thin Section Bearing for Your Application

Selecting the correct bearing is the foundation of longevity. Using the wrong size, type, or material—even if it fits—can dramatically shorten service life. When choosing a thin section bearing, consider:

Load Capacity: Determine both radial and axial load requirements. Bearings running above rated capacity can overheat, deform, or fail prematurely.

Speed Ratings: For high-speed applications, bearings must tolerate elevated rotational speeds without generating excessive friction or vibration.

Environmental Conditions: Bearings exposed to dust, chemicals, moisture, or extreme temperatures may require stainless steel, ceramic, or coated materials.

Precision Requirements: High-precision equipment may demand ABEC 7–9 or ISO P4–P2 tolerance bearings.

Manufacturer Consultation: Discuss your application with the manufacturer. Sometimes a slightly larger bearing or a different material can dramatically improve lifespan.

Practical Tip: In high-vibration environments, consider bearings with reinforced cages or hybrid ceramic elements to reduce wear and heat.

2. Ensure Precise and Careful Installation

Installation errors are a leading cause of bearing failure. Thin section bearings are especially vulnerable due to their delicate construction. Follow these practical steps:

Accurate Alignment: Use dial indicators, laser alignment tools, or precision gauges to align shafts and housings. Even 0.01 mm misalignment can cause uneven wear.

Controlled Mounting Force: Avoid hammering the bearing into place. Use hydraulic presses, alignment fixtures, or sleeve tools as recommended.

…

For more detailed information on how to extend the service life of thin-section bearings, please click to visit: https://www.lynicebearings.com/a/blog/how-to-extend-the-life-of-thin-section-bearings.html