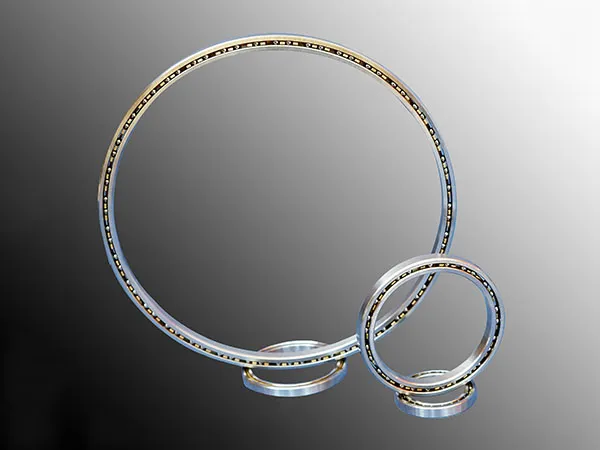

Thin section bearings are designed to be compact and lightweight, making them ideal for applications where space and weight are critical. However, their delicate nature requires specific maintenance practices to ensure their longevity and optimal performance.

Thin Section Bearings Maintenance Tips

1. Proper Installation:

Cleanliness is Key: Ensure the housing and shaft are free of any debris, dust, or contaminants before installation. Even small particles can significantly impact bearing performance and life.

Use Appropriate Tools: Never use a hammer or direct impact to install thin section bearings. Use an arbor press or specialized bearing installation tools that apply even pressure to the inner or outer ring, depending on the fit.

Avoid Brute Force: Forcing a bearing into place can deform the rings or damage the rolling elements, leading to premature failure. If a bearing doesn’t slide on easily, re-check the shaft or housing dimensions.

Correct Orientation: Ensure the bearing is installed with the correct orientation, especially if it’s a shielded or sealed type.

2. Lubrication:

Right Lubricant: Use the type of lubricant recommended by the bearing manufacturer. This could be grease or oil, and the specific type will depend on the bearing’s operating conditions (speed, temperature, load).

Optimal Amount: Over-lubrication can be as detrimental as under-lubrication, especially for high-speed applications. Excess grease can lead to increased friction, heat generation, and churning, while insufficient lubrication causes wear.

…

For more detailed information on thin-wall bearing maintenance tips, please click here: https://www.lynicebearings.com/a/blog/thin-section-bearings-maintenance-tips.html