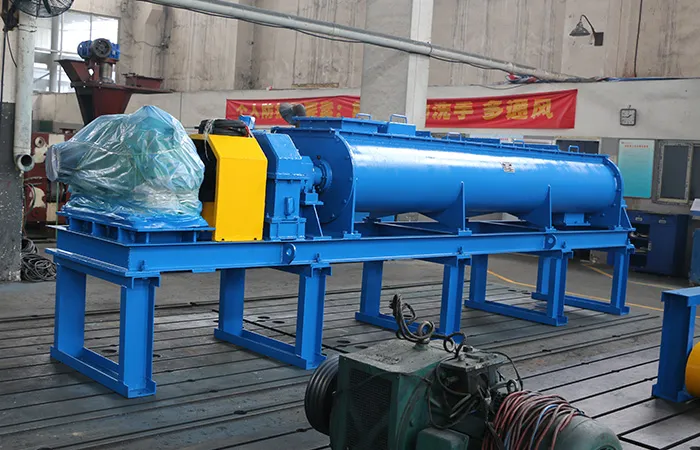

Lead screw welding rotators are specialized pieces of equipment designed to support and precisely rotate cylindrical workpieces for welding, polishing, assembly, and other fabrication processes. Their defining feature is the lead screw mechanism, which allows for accurate adjustment of the roller distance to accommodate a wide range of workpiece diameters.

Choosing the right model of lead screw welding rotator is crucial for optimizing your welding operations, ensuring efficiency, quality, and safety.

Lead Screw Welding Rotator Model Choose

1. Understand Your Workpiece Specifications:

Weight Capacity: This is the most critical factor. Determine the maximum weight of the cylindrical workpieces (pipes, tanks, vessels, etc.) you will be welding.

Welding rotators are typically rated in tons (e.g., 2T, 5T, 10T, up to hundreds of tons). Ensure the rotator’s capacity comfortably exceeds your heaviest workpiece.

Diameter Range: Identify the minimum and maximum diameters of the workpieces you need to rotate. Lead screw rotators offer adjustable roller distances to accommodate various diameters. Make sure the chosen model’s adjustment range covers your needs.

Length of Workpiece: For very long workpieces, you might need multiple sets of rotators (one drive unit and multiple idler units) to provide adequate support and

prevent sagging. Consider synchronization features if you plan to use multiple units.

Material of Workpiece: While most rotators are designed for general metals, consider if your material has specific requirements (e.g., very thin walls, sensitive surfaces that might need specialized roller coatings).

2. Consider the Type of Lead Screw Welding Rotator:

Lead Screw Adjustable (Manual or Motorized): This is the defining characteristic. The lead screw mechanism allows for precise adjustment of the roller distance to accommodate different workpiece diameters.

Manual Lead Screw: More economical, suitable for workshops with less frequent changes in workpiece diameter or when precise manual positioning is acceptable.

Motorized Lead Screw: Offers quicker and more precise adjustment, ideal for dynamic fabrication environments with frequent changes in workpiece sizes, reducing setup time and enhancing efficiency.

Self-Centering vs. Conventional (within Lead Screw Type):

Self-Centering Lead Screw Rotators: These are an enhanced version where the lead screw mechanism automatically centers the workpiece by moving both roller brackets equally in opposite directions. This is highly beneficial for varying diameters and frequent job changes, saving significant setup time and improving alignment accuracy.

Conventional Lead Screw Rotators: While still using a lead screw for adjustment, they might require more manual intervention for precise centering.

…

For more detailed information on how to choose the model of lead screw welding rotator click to visit:https://www.bota-weld.com/en/a/news/lead-screw-welding-rotator-model-choose.html