Preventing a linear vibrating screen from clogging is a critical operational challenge. Clogging, also known as blinding (when fine, sticky particles block the apertures) or pegging (when near-size particles get stuck in the apertures), severely reduces efficiency, lowers product quality, and increases downtime for cleaning.

How To Prevent Linear Vibrating Screen From Clogging

The solution is rarely a single fix but a combination of adjustments across equipment, operation, and material properties. Here is a comprehensive guide on how to prevent clogging, broken down into key areas.

1. Select the Right Screen Media (The Foundation)

| Screen Type | Description | Best For Preventing |

| Self-Cleaning Screen Mesh | Made of individual wires that can vibrate independently, held together by polyurethane or rubber strips. The differential movement of the wires actively dislodges stuck particles. | Pegging and Blinding. This is one of the most effective solutions for difficult, near-size, or slightly damp materials. |

| Slotted (Rectangular) Mesh | Openings are longer than they are wide. This provides more open area and reduces the chance of near-size particles getting stuck. | Pegging. Ideal for materials with elongated or flaky particles. Note: Sizing accuracy can be slightly reduced. |

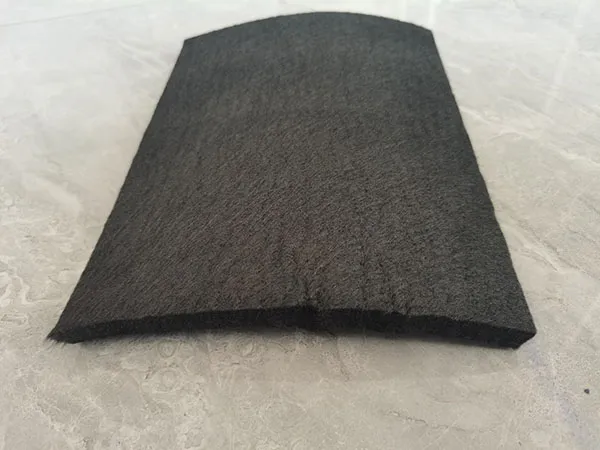

| Polyurethane or Rubber Screens | These materials are more flexible than steel. The openings are often tapered (wider at the bottom), which helps release particles. The natural flexibility helps “pop out” lodged material. | Pegging and high-impact applications. Excellent for abrasive or wet, sticky materials. |

| Woven Wire (Square Mesh) | The standard, all-purpose screen. While effective for many applications, it is the most prone to pegging with near-size, cubical particles. | General-purpose screening where clogging is not a major issue. |

2. Install Mechanical Anti-Clogging Systems

These are devices added to the screen deck to actively clear the mesh during operation.

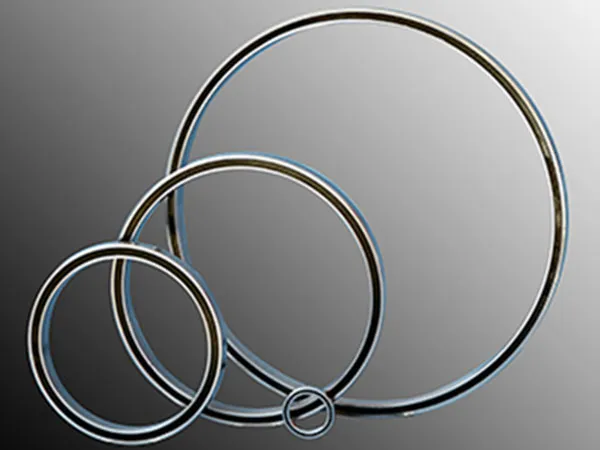

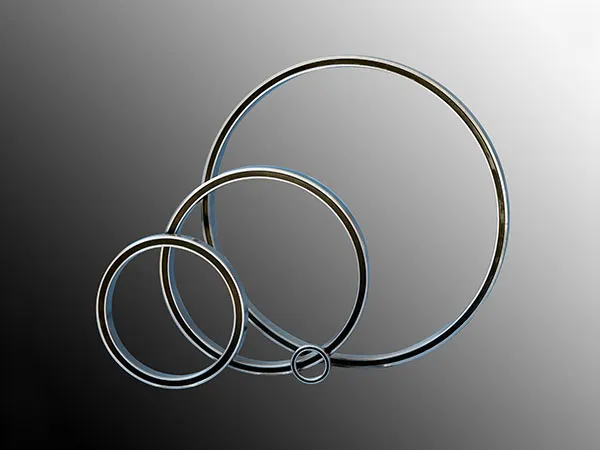

Bouncing Balls / Slider Rings:

How it works: Rubber balls or polyurethane rings are placed in a compartment beneath the screen mesh. The screen’s vibration causes them to bounce or slide around, constantly striking the underside of the screen. This impact dislodges particles that are pegged or blinded.

Best for: Dry, granular materials from fine to medium sizes.

Ultrasonic Deblinding Systems:

How it works: A transducer applies high-frequency, low-amplitude vibration directly to the screen mesh. This “micro-vibration” breaks the surface tension and static bonds between particles and the screen wires, preventing fine powders from blinding the mesh.

Best for: Very fine, dry, or static-prone powders (e.g., metal powders, pharmaceuticals, pigments). This is a high-performance, but more expensive, solution.

Rotary Brush Systems:

How it works: A motorized nylon brush rotates underneath (or sometimes on top of) the screen, continuously sweeping the mesh clean.

Best for: Greasy, oily, or fibrous materials that tend to smear or agglomerate on the screen surface.

…

For more detailed information on how to prevent vibrating screen mesh from clogging, please click here: https://www.hsd-industry.com/news/preventing-linear-vibrating-screen-from-clogging/