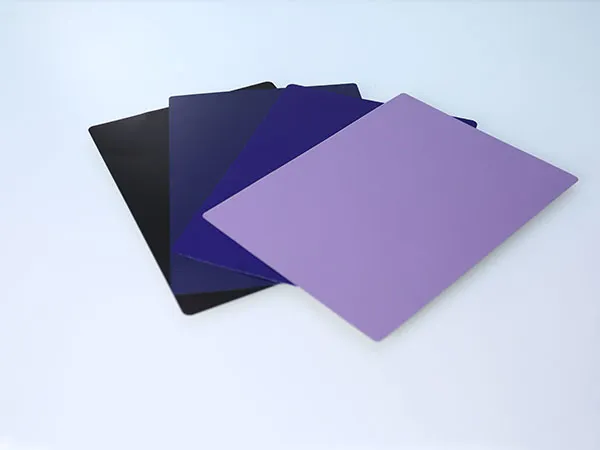

The price of a coated aluminum sheet can vary significantly due to a number of factors. Based on available data, the price per square meter can range from approximately $20 to over $1000 USD depending on the specifications.

Price Range Per Square Meter for Coated Aluminum Sheets

Economy (PE coating, thinner thickness, standard colors): Approximately **$15 – $30** per square meter

Mid-range (PVDF coating, medium thickness, common colors): Approximately **$30 – $50** per square meter

High-end (PVDF triple coating or nano-coating, thicker, special colors or custom sizes): May exceed **$50** per square meter

Key Factors Affecting the Price of Coated Aluminum Sheets

1. Thickness of Aluminum Sheet

This is the most direct factor affecting price. The thicker the aluminum sheet, the more raw materials required, and the higher the price. For example, a 0.3mm-thick coated aluminum sheet of the same size and coating will be significantly cheaper than a 2.0mm-thick one. When selecting, determine the required thickness based on your application scenario (e.g., interior decoration, exterior curtain walls, signage, etc.).

2. Type of Coating

The coating is one of the core values of coated aluminum sheets, determining the material’s weather resistance, color stability, and aesthetic appeal. Different types of coatings vary significantly in price:

Polyester (PE) Coating: This is the most common coating, offering good value for money and suitable for indoor use or outdoor environments with low weather resistance requirements.

Fluorocarbon (PVDF) Coating: Offers exceptional weather resistance and UV protection, with long-lasting color, making it the preferred choice for outdoor building facades. PVDF-coated aluminum panels typically cost more than PE-coated ones.

Nano-PVDF Coating: Adds self-cleaning functionality to PVDF, resulting in a higher price.

Other Special Coatings: Such as antimicrobial coatings, fire-resistant coatings, etc. These special-function coatings also increase the price.

3. Coating Process & Brand

Coating Methods: Common methods include roll coating and spray coating. Roll coating is more efficient and cost-effective, while spray coating can achieve more complex shapes and details.

…

For more detailed information about the price of color-coated aluminum sheets per square meter, please click here:https://www.dw-al.com/a/news/coated-aluminum-sheet-price-per-square-meter.html