Blog

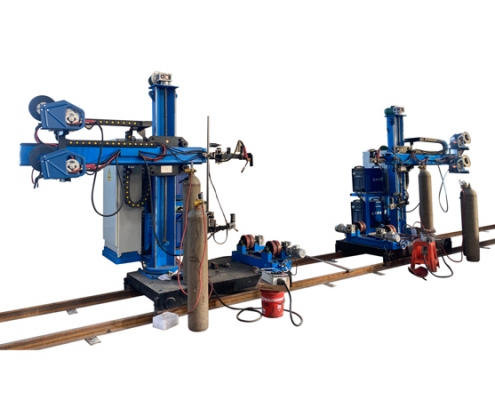

Why Customized Welding Rotator Solutions Are Essential for Modern Pressure Vessel Fabrication

NewsIn the heavy manufacturing sector, pressure vessel fabrication is a process where precision determines safety, quality, and long-term performance. Any deviation—whether a misalignment during rotation or an uneven welding seam—can compromise…

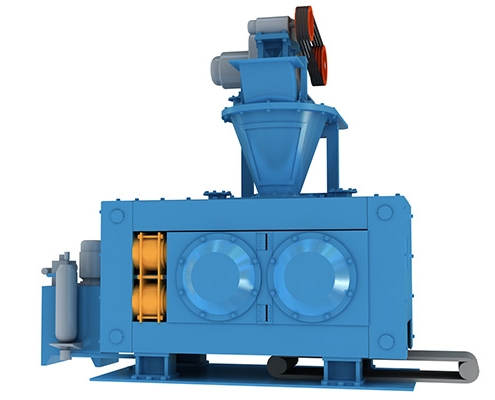

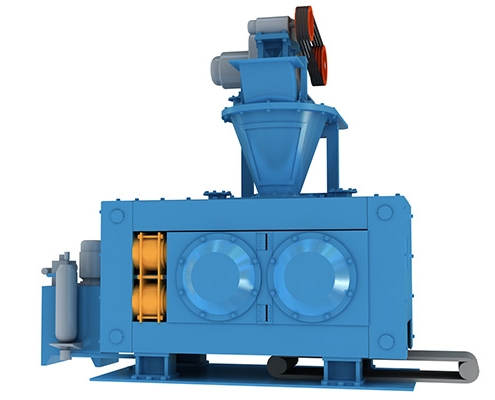

Ball Press Machine Installation and Commissioning Service: Laying a Solid Foundation for Stable, Long-Term Operation

NewsIn industrial production lines, a ball press machine is far more than a standalone piece of equipment. It is a core unit that directly influences material forming quality, output stability, and overall production efficiency. Whether the machine…

Ultimate Guide: How to Adjust Ball Density in a Ball Press Machine for Maximum Efficiency

NewsControlling the density of balls in a ball press machine is critical for producing consistent, high-quality pellets. Whether you manufacture fertilizer, feed, or other granular products, small adjustments can significantly impact production…

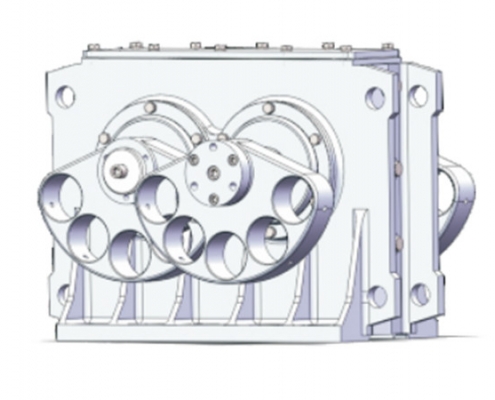

How to Prolong the Service Life of Ball Press Machine Rollers

NewsBall press machines are indispensable in industries such as feed production, fertilizer manufacturing, and biomass pellet processing. At the core of these machines are the rollers, responsible for compressing raw materials into dense, uniform…

Energy-Saving Tips for Operating a Ball Press Machine: Practical Strategies for Lower Costs and Higher Efficiency

NewsIn modern industrial production, the cost of energy has become a major factor affecting overall profitability. For factories using ball press machines—equipment designed to compact powders into uniform, high-density briquettes—how efficiently…

Benefits of Using a High-Frequency Vibrating Screen Exciter in Industrial Screening

NewsIn industries such as mining, quarrying, construction materials, and chemical processing, efficient material screening is a critical step that directly affects product quality, production capacity, and operating costs. As material specifications…