Blog

How to Choose the Right Graphite Crucible for Your Foundry

NewsIn the foundry industry, choosing the right equipment is crucial for production efficiency and product quality. As the core vessel in the metal smelting process, the performance of the graphite crucible directly impacts smelting results, energy…

Thin Section Ball Bearings: The Perfect Balance of Precision and Lightweight Design

NewsIn today’s fast-evolving industrial landscape, the demand for compact, lightweight, and high-precision equipment continues to grow. Among the many engineering innovations that meet these needs, thin section ball bearings have emerged as a…

Precision Wins: The Art and Practice of Accurate Alignment for Thin-Section Bearings

NewsAt the heart of modern industrial operations, precision mechanical design demands unparalleled efficiency and reliability. Thin section bearings, with their unique advantages of being lightweight, slim, and highly precise, are emerging as the…

How to Reduce Friction in Thin Section Bearings

NewsThin-section bearings are becoming increasingly popular in the design of precision machinery and compact equipment due to their unique advantages of lightweighting and space-saving features. However, optimizing the performance of these bearings,…

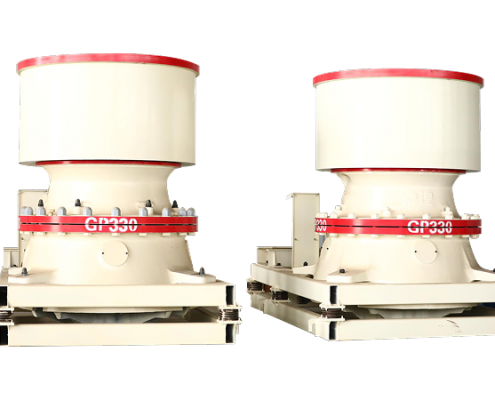

Energy-Saving Cone Crusher: Purchasing Guide and Core Advantages Analysis

NewsIn heavy industries like mining, metallurgy, and construction, crushing equipment is an essential component of production. With the global adoption of energy conservation, emission reduction, and sustainable development, energy-saving cone crushers…

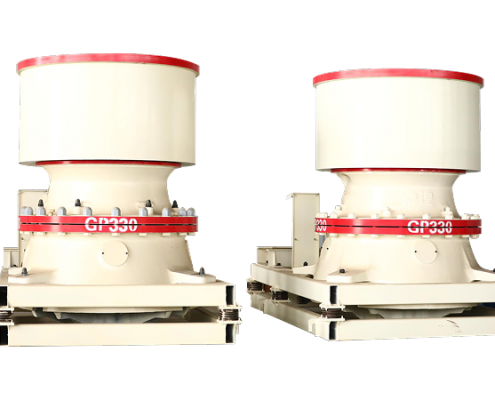

High-Performance Cone Crusher: The Rock-Breaking Powerhouse from Giant Rock Coarse Crushing to Premium Fine Crushing

NewsAt the forefront of rapidly evolving global mining operations, high-quality construction aggregate production, and resource recovery within the circular economy, high-performance crushing equipment remains the cornerstone of successful production…